Intretech’s Design & Engineering Solutions: Innovation Meets Precision

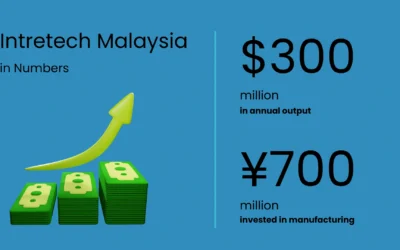

Transforming innovative ideas into tangible, market-ready products with our cutting-edge design and engineering services. Our global team of over 1,600 skilled engineers specializes in the integration of hardware, software, and AI technologies, ensuring your project benefits from the latest advancements in design and functionality.

Our approach is holistic, ensuring that every aspect of the product, from functionality and durability to aesthetics and marketability, is meticulously crafted to meet the highest standards.

Our end-to-end service package is meticulously designed to make manufacturing easy and efficient for our clients. From quick setup facilitated by a dedicated customer onboarding team to global support, we guarantee efficiency and responsiveness at every step.

Industrial Design

Our Industrial Design experts are focused on merging form and function, using advanced CAD tools and 3D modelling to create compelling and ergonomic designs. We incorporate user feedback and market trends, ensuring each product not only looks great but also aligns perfectly with user needs and stands out in the competitive market.

Firmware and Software

Intretech’s Firmware and Software solutions focus on enhancing product functionality and security. Our skilled engineers develop scalable, robust firmware and software that integrate seamlessly with hardware, supporting rapid updates and advanced smart product features.

Industrialisation

Bridging the gap between innovative design and mass production, we focus on scaling designs for large-scale manufacturing, ensuring that each product can be produced efficiently and to the highest quality standards. Our process involves rigorous testing and refinement, streamlining production lines, and integrating supply chain logistics.

By closely managing the transition from prototype to full-scale production, Intretech guarantees that new products are market-ready, optimizing both time-to-market and cost-effectiveness.

Design for Manufacturing

Our Design for Manufacturing (DFM) approach optimises products for efficient production from the outset. By addressing potential manufacturing challenges early in the design process, we streamline production, reduce costs, and ensure high-quality outcomes consistently across all products.

Design for Automation

Our contract manufacturing services emphasize design for automation through detailed audits, including product and process readiness assessments and factory evaluations. We employ a robust Automation Framework to align with your project’s specific requirements, complemented by a Tailored Automation Roadmap. This strategic approach ensures that your manufacturing process is optimized for efficiency and scalability, right from the outset.

Our Cleanroom Facilities

Intretech’s cleanroom facilities encapsulate the essence of modern manufacturing. The cleanliness level of these environments is often rated at 10k ensuring a pristine climate conducive to manufacturing sensitive optical and medical devices.

Our goal is to make your product journey seamless, efficient, and innovative, setting new standards in the industry.

Explore more related content

The Innovations that Shaped Manufacturing

The Innovations that Shaped Manufacturing in 2024 Every year, different trends drive every industry, and manufacturing...

Intretech Shines at PMI Supplier Summit: A Collaborative Vision for Excellence

Intretech Shines at PMI Supplier Summit: A Collaborative Vision for ExcellenceIntretech Ltd, a forerunner in the...

How is Generative AI Shaping the Future of Manufacturing Design and Prototyping?

How is Generative AI Shaping the Future of Manufacturing Design and Prototyping?The use of artificial intelligence...