Your products aren’t designed for automation. This is costing you millions.

Why should I design for automation?

Manufacturers are desperately looking for ways to produce, cheaper, faster, and more sustainably (See manufacturing trends 2022). Following a set of basic guidelines at the design stage, ensures that any experienced contract manufacturer can implement automation for your products.

While a lot of technical considerations need to be put into place, there are some steps that you can take, to ensure that automation is embedded as early as possible in the design stage of every product.

Following these guidelines, ensures that you are covering the basics. When your products are designed for automation, it makes it easy for your contract manufacturer to offer affordable and realistic automation solutions:

Plan your products for ramping up.

1/6

It’s important to think about how your product or sub-assembly is going to ramp up in volumes. Will it be slower over time? Or are you trying to produce as many as possible to benefit from first mover advantage?

Until recently, the only available option was to build custom automation solutions. Whilst it may give best unit cost, it’s the riskiest option available.

An alternative is to approach it with a modular automation mind set. Think of solving ‘bottleneck’ processes with automation, and combine steps with manual assembly. This approach allows initial volumes to be lower (in the 1000’s), and you can scale up the line by adding more ‘modules’ when needed. Gradually you build up to a fully automated manufacturing line producing millions of units.

- Automation for consumer electronics and medical devices is normally implemented when high volumes are needed, typically 100k+ a month. Modular automation design works with lower volumes.

- Historically custom automation lines take 12-18 months to design, manufacture and approve, with CAPEX in the multi-millions of dollars.

- This can be high risk, often products have design changes, meeting target specifications or simply do not meet sales expectations due to quality or market conditions.

If your SKUs will increase, plan for it early.

2/6

Adding different SKUs after the product is fixed, will cause issues, particularly if you are building a custom automation line.

In an ideal world, you want a single manufacturing line that can cater for multiple SKUs, with little changeover downtime, and that doesn’t require a huge capex investment. Thankfully this option is available. An experienced contract manufacturer with an automation mindset, should be able to offer you this solution. If they don’t do it, keep searching, they are out there.

The way these systems work, to cater for multiple SKUs is simple. Your modular assembly line has different ‘feeder’ modules, that store different variants of parts (colours/screw types, etc) and can be swapped over quickly. This applies more to products that use a similar architecture, but need to change the type based on end-user requirement like colour, cosmetic type, performance, flavours, and quality.

Design for Automation Checklist

- Are you making just one version, or will there be multiple versions of your product (SKU’s)?

- If there are multiple versions, you need to consider how your automation line will be able to cater for the flexibility.

- If your product uses liquids or glues, lines need to be ‘purged’ so this needs to be considered.

- Stay away from customised automated lines, this can introduce a lot of complexity and affect downtime to switch from one version to another.

Artificial Intelligence (AI) and Machine Learning (ML) provide futureproofing.

3/6

Building in AI and ML into your automation is critical. It allows you to reduce the amount of manual programming, increases the quality of parts and improves the precision to desired specification. Combining camera vision systems with 3-6 axis robots, can be a very powerful way to cater for multiple variants in your products.

Until recently, this technology was only available for a few manufacturers that could afford it. Thanks to the advancements in the field, new modular automation systems offer this technology without breaking the bank.

By implementing this into a modular automation line, you can create a very flexible and smart, manufacturing system, that can be self-adjusted, modified quickly and efficiently.

- Artificial intelligence (AI) plays a big role in automation and can be the key differentiating factor to fully optimise your system.

- You can combine camera technologies with machine learning (ML) to perform intelligent decisions during the assembly. This is especially useful if you are making different variants of the product and want to maximise the unit per hour (UPH).

- It is possible to program the automated line to dynamically change the properties of components during the assembly, to optimise or meet a specific performance specification. This is called ‘smart manufacturing’. For example you can adjust the length of a wire slightly each time, to ensure best fit within a tight tolerance.

To ship or not to ship. Stay close to your key markets…

4/6

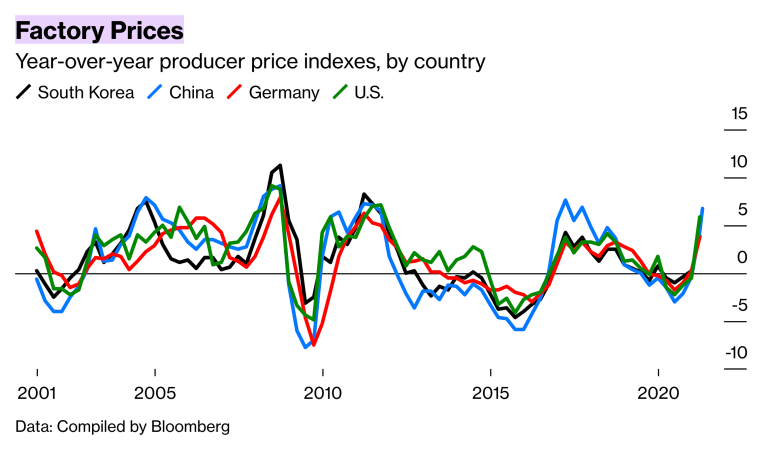

Let’s face it, manufacturing in China isn’t as cheap as it used to be.

You need to do an analysis to compare the cost savings from manufacturing in China (lower operator costs) versus the cost of shipping. Worry not, we have done it for you, these are the highlights:

- Shipping and logistics costs from China are now x10 higher, than they were, just six months ago.

- China labour rates have steadily risen over the past 5-10 years by 30%, as standard of living increases.

- Shipping is a key factor, rates for containers have increased up to x10 price (from $2000 to $20,000).

- Cost/availability of Air freight is limited, the big players are taking all the shipping slots years in advance, to ensure their delivery for seasonal products.

- There is also a shortage of shipping containers, this further squeezes the supply/demand for shipping by sea, pushing up air freight costs.

Source: Bloomberg

This opens the doors to new manufacturing options that, without automation, weren’t possible. For example, your products can now be manufactured in eastern Europe, where labour costs are marginally higher than China. Your shipping and logistics costs will also be lower, translating all these reductions to your manufacturing costs.

Design for Automation Checklist

- Where are you planning on selling your finished goods?

- Will it be in a specific continent like EU or a country like the USA?

- Will your product benefit from manufacturing closer to your key markets?

Design for automation = Design for sustainability.

5/6

Think of your product, and all the processes involved. Then reduce to as minimum as possible, the number of steps for assembly. Once you have a clear picture of your work instructions, think of how to group some of those processes together.

Having this under control, an experienced automation-focused contract manufacturer, can take it a step further and advice on how to fit those processes in the smallest number of automation modules, building an ultra-efficient automated assembly line.

- Whilst custom automation can bring benefits for high volume/high mix products, it does require a lot of resources, both in the manufacture of the equipment and the ongoing energy needs for mass production, often running consistently for months.

- The environmental impact is clear, manufacturing of products far outweighs the impact those actual products have when actually in use during their lifetime.

- Automation lines are not linked to sustainability, and this is something that needs to be considered, not only in the design of the product, but also in the design of the automation equipment itself.

Risk mitigation to improve chances of success

6/6

Changes in design due to user feedback or quality reasons are normal for high complexity projects. When designing for automation, make sure that you are building in flexibility. This is a good way to absorb design changes when they happen.

Also calculating key product metrics like ROI, volume and capacity will be expected, to understand risk, and convince your key stakeholders. CAPEX investment into automation is usually one of the biggest barriers to entry.

This is why products are often launched with a manual assembly process, where initial CAPEX is lower, even if the gains from automation are obvious in the mid to long term.

Design for Automation Checklist

- Try to spec off-the-shelf components as much as you can or use systems where less customisation is needed. This will lower your exposure to long lead items having to depend on certain suppliers.

- Changes in design are inevitable for complex projects with a lot of unknowns. You can use Design FMEA and Process FMEA to highlight where the risks are and then add in flexibility into your product design to cater for those changes.

- Manage risk by doing thorough FMEA and tolerance analysis to understand risks. Put in place risk mitigations for high ranked risk items. You can also take an agile approach and focus on certain parts or sub-assemblies first, and then build more automation capability from there.

- At some point a key stakeholder will have to agree and sign off some CAPEX.

Think about design for automation as soon as you can, preferably whilst in product development and R&D. All options should be on the table, from custom automation to modular automation systems. Working closely with your contract manufacturer is important, and when in doubt, always look for a second opinion.

Designing for automation speeds up the development process and time to manufacture, it lowers risk and cost of change, which is critical in situations where first mover advantage is needed.

I’ve seen it often enough now, it really pays to think about implementing design for automation as early as possible.

Explore more related content

12 reasons why Microfactories are the future of manufacturing

12 reasons why Microfactories are the future of manufacturingMicrofactories: The Future A few days ago, Peter Goodman...

6 Takeaways from the European Commission’s 2022 Green Deal.

6 Takeaways from the European Commission’s 2022 Green Deal.Last week, the European Commission presented a new package...

5 predictions for manufacturing in 2022

5 predictions formanufacturing in 2022Manufacturing Trends in 2022With 2022 here, it’s exciting to imagine what this...