Understanding Scope 1, 2, 3 Emissions and how they affect production

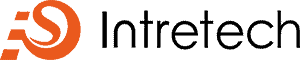

It is essential to understand the differences between Scope 1, Scope 2, and Scope 3 emissions for manufacturing companies that seek a reduction in their carbon footprint and increased sustainability. The GHG Protocol has categorized these so companies can identify all emissions managed along their value chain.

Scope 1 Emissions: Direct Emissions from Owned or Controlled Sources

Scope 1 emissions are direct greenhouse gas emissions that emerge from sources that are owned or controlled by the company. In the manufacturing sector, emissions mostly come from places such as on-site fuel combustion from boilers, furnaces, and company-owned vehicles. For example, the burning of natural gas to power industrial processes releases CO₂ directly into the atmosphere. Managing these emissions involves implementing energy-efficient technologies and regular maintenance to ensure that equipment has smooth operations.

Scope 2 Emissions: Indirect Emissions from Purchased Energy

Scope 2 emissions are indirect GHG emissions. These emissions are a result of the consumption of purchased electricity, heat, or steam. Since these emissions occur at the facilities of the energy supplier, they are attributed to the purchasing company. Scope 2 emissions can be reduced by increasing energy efficiency and sourcing energy from renewable providers. Switching to renewable sources of energy will not only reduce emissions but may also save costs in the long run.

Scope 3 Emissions: All Other Indirect Emissions in the Value Chain

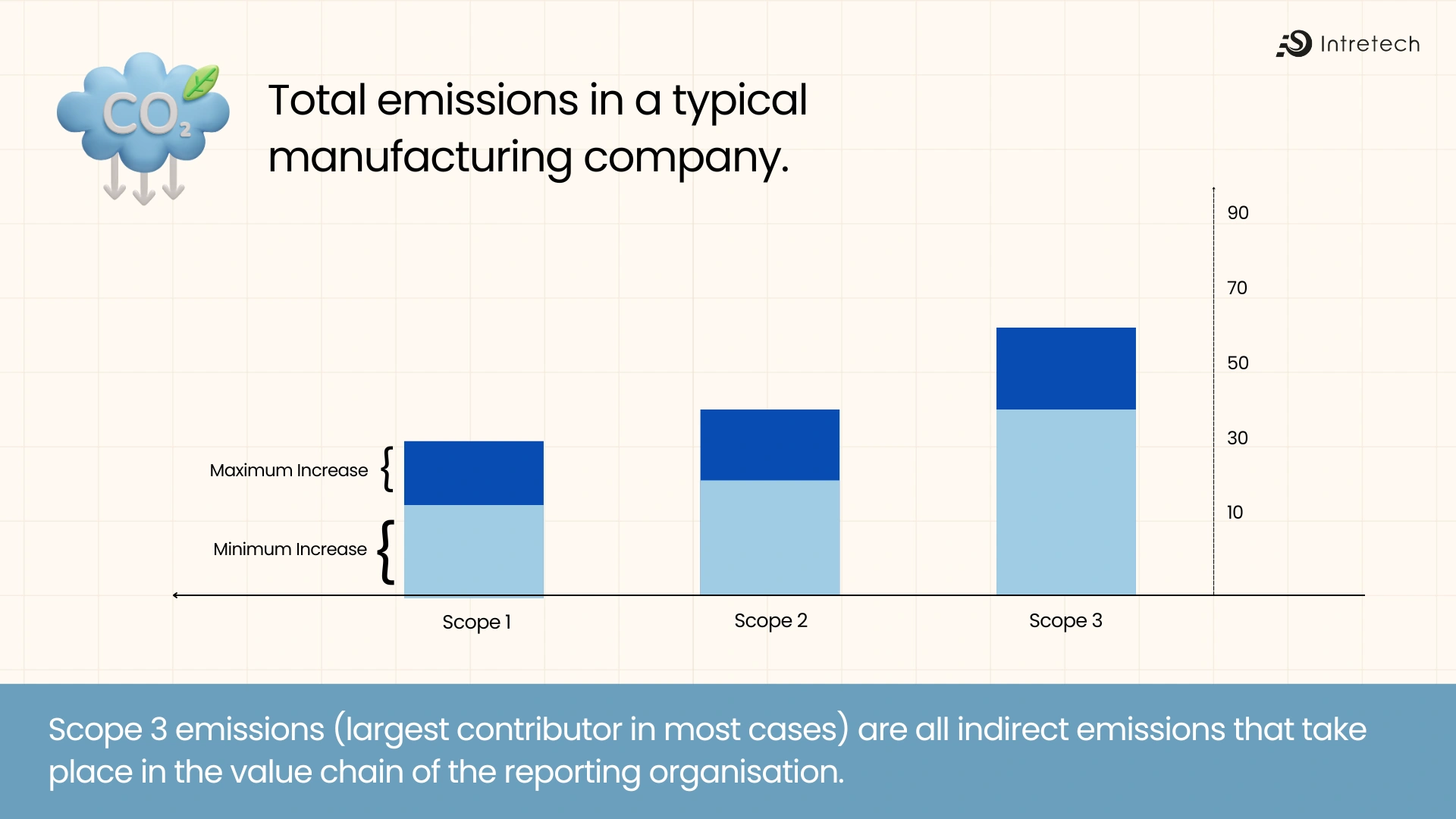

Scope 3 emissions are all indirect emissions that take place in the value chain of the reporting organization, excluding Scope 2 emissions. This category is normally the largest and most difficult to control since it embraces both upstream and downstream activities.

Upstream activities include extraction or production of purchased goods and services, capital goods, and transportation. Downstream activities relate to processing, use, and end-of-life treatment of products sold. For example, emissions from a manufactured product being used by a customer are Scope 3. Measures of emission will therefore necessitate coordination with suppliers and customers for effective sustainability during the entire product life cycle.

Read more about: Scope 3 Inventory Guidance

Emissions Impact on Manufacturer

Manufacturing is one of the sectors that contribute to the net emissions seen in the world today. In 2022, according to the International Energy Agency (IEA), emissions from industry dropped by 1.7% to 9.2 gigatonnes, signifying that there has been some progress but also a huge influence of manufacturing on the environment. However, Scope 1 and 2 emissions are relatively easy to manage since these are those under the control of the company. On the other hand, Scope 3 emissions account for the majority of a company’s total GHG emissions. Therefore, it is essential to address this through holistic sustainability strategies.

Control Measures for Emissions

Energy Efficiency: The use of efficient technologies and practices reduces both Scope 1 and Scope 2 emissions. This includes the replacement and upgrading of equipment, optimising production processes, and enhancing facility insulation.

Renewable Energy: Source substitution by utilizing renewable energy source like solar and wind power for on-site use reduces Scope 2 emissions. The companies can acquire on-site generation or renewable energy credits.

Supply Chain Engagement: Interaction with suppliers regarding encouragement of practices related to sustainable practices helps the companies reduce their upstream Scope 3 emissions by creating sustainability standards for suppliers and improving their performance towards the environment.

Product Design: Designing products with sustainability in mind can reduce downstream Scope 3 emissions. This includes creating products that are energy-efficient, durable, and recyclable, thereby minimizing environmental impact during use and at end-of-life.

Transportation Optimisation: Optimising logistics to reduce transportation emissions can impact both upstream and downstream Scope 3 emissions. Strategies include consolidating shipments, selecting energy-efficient transportation modes, and improving route planning.

Challenges in Managing Emissions

Whereas Scope 1 and 2 emissions fall directly within a company’s control, managing Scope 3 is quite a challenging task due to the following reasons:

Data Collection: Data collection from suppliers and customers might be very difficult, especially in the case of a huge and complex supply chain.

Influence: A company may have less influence over external parties’ practices, making it difficult to make any changes that could reduce the emission.

Double Counting: There’s a risk of double counting emissions, as Scope 3 emissions for one company may be Scope 1 or 2 emissions for another.

Determining and controlling Scope 1, 2, and 3 emissions is highly relevant for manufacturers that are focused on sustainability. Through complete strategies which address all the emission scopes comprehensively, companies can reduce their environmental footprint, achieve the compliance barriers, and respond to the expectations of consumers and stakeholders in terms of sustainability.

Another effective method to reduce your environmental footprint, is the adaption of Circular Economy. Explore what is it in detail here: Circular Economy: A sustainable innovation.

Explore more related content

Air Purifiers and Electricity Usage: Do They Break the Bank?

Optimising Energy Efficiency in Air Purifiers: Engineering and Procurement StrategiesThe design and production of...

An Era of Development for Automotive Optics

An Era of Development for Automotive Optics: Merging Design and DevelopmentThe automotive optics industry is evolving....

The Innovations that Shaped Manufacturing

The Innovations that Shaped Manufacturing in 2024 Every year, different trends drive every industry, and manufacturing...