Elevate Your Manufacturing with

Precision Injection Molding

Our cutting-edge, fully electric injection molding lines, coupled with automated packaging solutions, ensure the consistent delivery of premium-quality plastic products worldwide, including to key markets in Europe.

From design to mass production

Our engineering and business teams are dedicated to assisting you at every stage of your product development journey. From initial concept and design, where we employ the latest in CAD and simulation software, to ensure your ideas are both innovative and manufacturable, to precise tooling and mold making, where our advanced machinery guarantees that every detail is crafted to perfection. We provide comprehensive support in material sourcing, leveraging our global network to obtain the highest quality materials that meet your specific requirements.

Once production begins, our commitment to excellence does not waver. We oversee the entire manufacturing process, guaranteeing that each phase, from initial runs to full-scale production, meets our exacting quality standards. Our logistics services guarantee timely delivery, real-time tracking and reliable distribution channels. Whether you require small batches or mass production, Intretech is equipped to handle your needs efficiently and effectively.

Ready to bring your product from concept to reality?

Let’s get started!

Sets of annual tooling capacity

Injection molding machines

Water based spray paint line

Global manufacturing locations

Why Choose Intretech for Injection Molding?

With a global presence and a commitment to excellence, Intretech is a market leader in precision injection moulding technology. Our advanced, fully electric injection moulding lines and automated packaging solutions provide consistently high-quality plastic products at scale.

Comprehensive Injection Molding Services

Our services cover the full spectrum of the manufacturing process, guaranteeing seamless integration and optimal efficiency:

- Design and Engineering: Our team of over 1,600 engineers utilizes the latest design and engineering technologies to create innovative solutions tailored to your needs.

- Tooling and Mold Making: We offer custom mold design and high-precision machining to ensure that every component meets exact specifications.

- Production and Quality Control: Our state-of-the-art manufacturing facilities are equipped with automated systems for rigorous quality control and lifecycle testing, ensuring the highest standards of product quality and durability.

Surface Treatment and Painting Capabilities

Intretech stands out in the industry with our exceptional surface treatment and painting capabilities, driven by our cutting-edge 1000m+ water-based spraying line. This system is equipped with advanced digital controls that allow for precise adjustments, enabling a range of flexible coating options—from one-coating & one-dry off to four-coating & four-dry off.

The line has been designed specifically for water-based paints and includes an extra-long drying section that guarantees high-quality finishes while adhering to strict environmental standards. The ability to control temperature and humidity precisely ensures consistent and superior results, making it a vital asset for delivering top-tier products across various sectors.

Our expertise extends further into CMF (Color, Material, Finishing) capabilities, where we offer a broad spectrum of surface treatments and painting techniques. From In-Mold Labeling (IML) and dual injection to sophisticated anodizing and hydrographic transfer printing, Intretech provides unmatched versatility in product design.

These advanced surface treatment options not only enhance the aesthetic appeal but also ensure that our products meet the highest functional and design standards, staying ahead of market trends and customer expectations.

Industries We Serve

Intretech’s precision injection molding services cater to a wide range of industries, providing customized solutions that meet specific industry requirements:

Medical Devices

Automotive

Consumer Electronics

Partner with Intretech to meet your industry-specific needs.

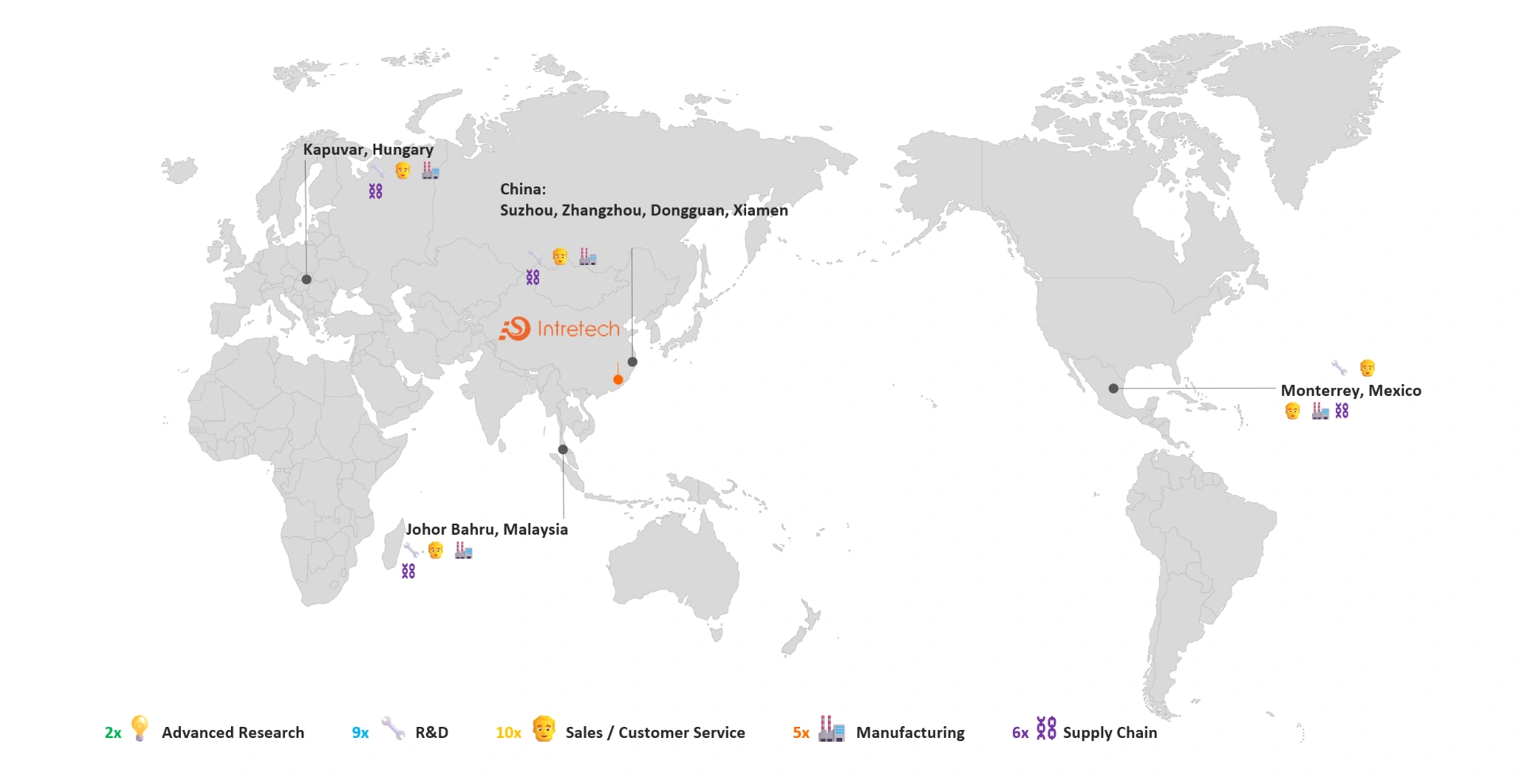

Intretech’s extensive network of manufacturing facilities spans across key locations worldwide, ensuring that we can deliver high-quality precision injection molding services wherever you are.

Our strategically positioned factories in China, Mexico, Hungary, and Malaysia are equipped with advanced technologies and staffed by expert teams, enabling us to meet the diverse needs of our clients efficiently and effectively.

Explore the map below to see where our world-class manufacturing capabilities are located and how we can support your business on a global scale.

Our Commitment to Sustainability

At Intretech, sustainability is at the core of our operations. We employ environmentally friendly practices and advanced technologies to minimize waste and reduce our carbon footprint. Our Sustainability Excellence Framework ensures that all our processes are aligned with global standards for environmental responsibility.

Partner with Intretech

Partnering with Intretech means leveraging our extensive expertise, innovative technologies, and global reach to bring your products to market with unmatched quality and efficiency. Contact us today to learn more about how our precision injection molding services can elevate your manufacturing capabilities.

Our Services

Intretech offers a comprehensive range of services to support your manufacturing needs:

- Mold Design:

Crafting innovative and efficient mold designs to meet your specific requirements. - Mold Opening:

Expertly managing the initial phase of mold creation to ensure accuracy and precision. - Mold Adjustments and Maintenance:

Providing ongoing support to maintain and adjust molds for optimal performance. - High Precision Tooling:

Utilizing advanced technology for the creation of precise and reliable tooling. - Injection Molding:

Delivering high-quality injection molding services for a variety of applications.

- Printing:

Offering custom printing solutions to enhance your products. - Tamping:

Providing specialized tamping services to ensure product integrity. - Component Assembly:

Assembling components with precision and efficiency. - Material Sourcing:

Ensuring the highest quality materials are used in your projects. - Automation Solutions:

Implementing automation strategies to improve efficiency and scalability. - Logistics Services:

Managing logistics to ensure timely delivery and optimal supply chain management.

Ready to take your manufacturing to the next level?

Contact us today to discuss your precision injection molding needs.

Explore more related content

Quality Assurance in PCB Manufacturing: Best Practices and cutting edge Techniques

Quality Assurance in PCB Manufacturing: Best Practices and Cutting-edge TechniquesEnsuring the quality of Printed...

How Malaysia Became Southeast Asia’s Leading Manufacturing Hub

How Malaysia Became Southeast Asia's Leading Manufacturing HubAs manufacturing has become increasingly globalised,...

Nearshoring to Mexico: A Strategic Opportunity for Smart Manufacturing

Nearshoring to Mexico: A Strategic Opportunity for Smart ManufacturingIn recent years, nearshoring in Mexico has...